Raft bottom main bar steel preparation is the process in which we prepare steel according to the bar bending schedule and install it at the bottom of the raft. The steel for the raft bottom main bar is used in the bottom part of the raft and is always installed on cover blocks to ensure that RCC concrete reaches the bottom of the raft. In this article, we will discuss all the processes involved in steel preparation and installation for the raft bottom main bar one by one.

step 1 – identify

In the first step of raft bottom main bar steel preparation, we read the bar bending schedule to determine the thickness of steel to be used. Then, we find the variation by subtracting the minimum cutting length from the maximum cutting length and dividing it by the total number of bars. The minimum length is the first cutting length, and we add the variation to it to get the second cutting length. We continue adding the variation to each subsequent cutting length. The first cutting length should match the minimum length given in the bar bending schedule, and the last cutting length should match the maximum length. The total length of the steel should be between the minimum and maximum cutting lengths, neither more nor less.

step 2 – preparation

In the second step, we bend the steel according to the bending angles specified in the bar bending schedule, using a bending machine from maximum to minimum lengths. This work is done one by one by construction workers to ensure there are no mistakes and that all steel lengths and angles remain the same.

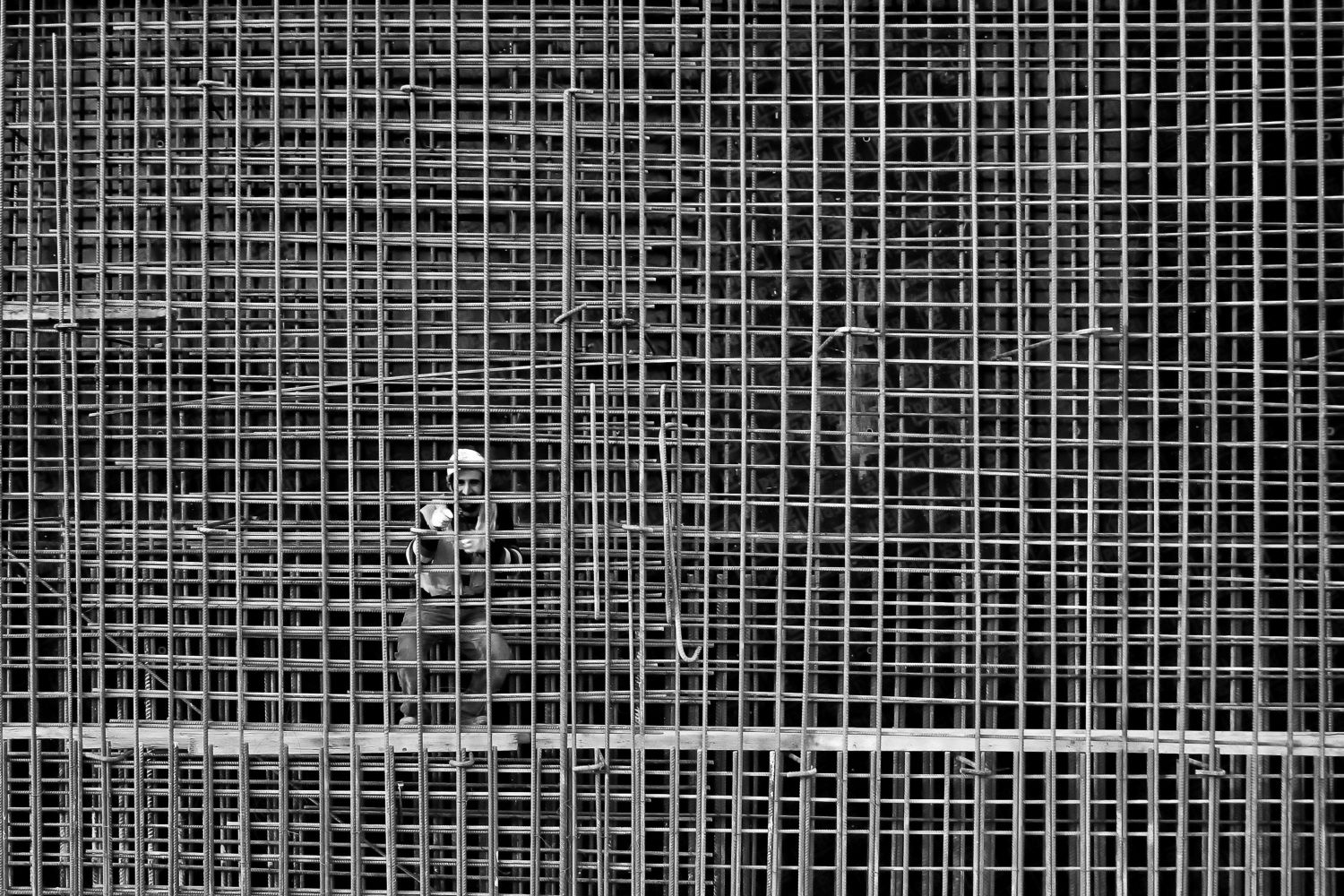

step 3 – installation

In the third step of raft bottom main bar preparation, we install all the prepared steel on the raft over the cover blocks one by one. Ensure that all the steel bars are spaced at a specific distance as mentioned in our BBS. Construction workers install the steel on the raft from the minimum to the maximum length, one by one.

step 4 – process

In the fourth step of raft bottom main bar installation, we place binders on the steel at a fixed distance and tie them using binding wire. Then, we install the steel chairs prepared according to the BBS. After this, we proceed with the preparation and installation process for the raft top main bar steel.

conclusion

In conclusion, the preparation and installation of the raft bottom main bar steel are crucial steps in ensuring the strength and stability of the raft foundation. By following the bar bending schedule meticulously and using precise measurements, construction workers can effectively prepare, bend, and install the steel bars. Each step, from reading the BBS to the final installation, requires careful attention to detail and adherence to specifications. This systematic approach ensures that the raft foundation is well-supported, allowing for the proper distribution of concrete and overall structural integrity.

Is there a code for rebaring?

Yes, there is a code for rebaring which provides guidelines and standards for reinforcing steel in construction. It includes specifications for bending, cutting, and placing rebar to ensure structural integrity and compliance with design requirements.

What is a bar bending schedule?

A bar bending schedule (BBS) is a detailed list that specifies the type, size, length, and bending details of the steel reinforcement bars used in a construction project. It ensures accurate preparation and placement of rebar according to the design requirements.

What is a bar mark in reinforcement?

A bar mark in reinforcement is an identification label assigned to each type of rebar in the bar bending schedule. It helps in distinguishing different bars and their specific details, ensuring correct placement and compliance with the construction design.